Why Every Homeowner Should Understand Electrical Testing

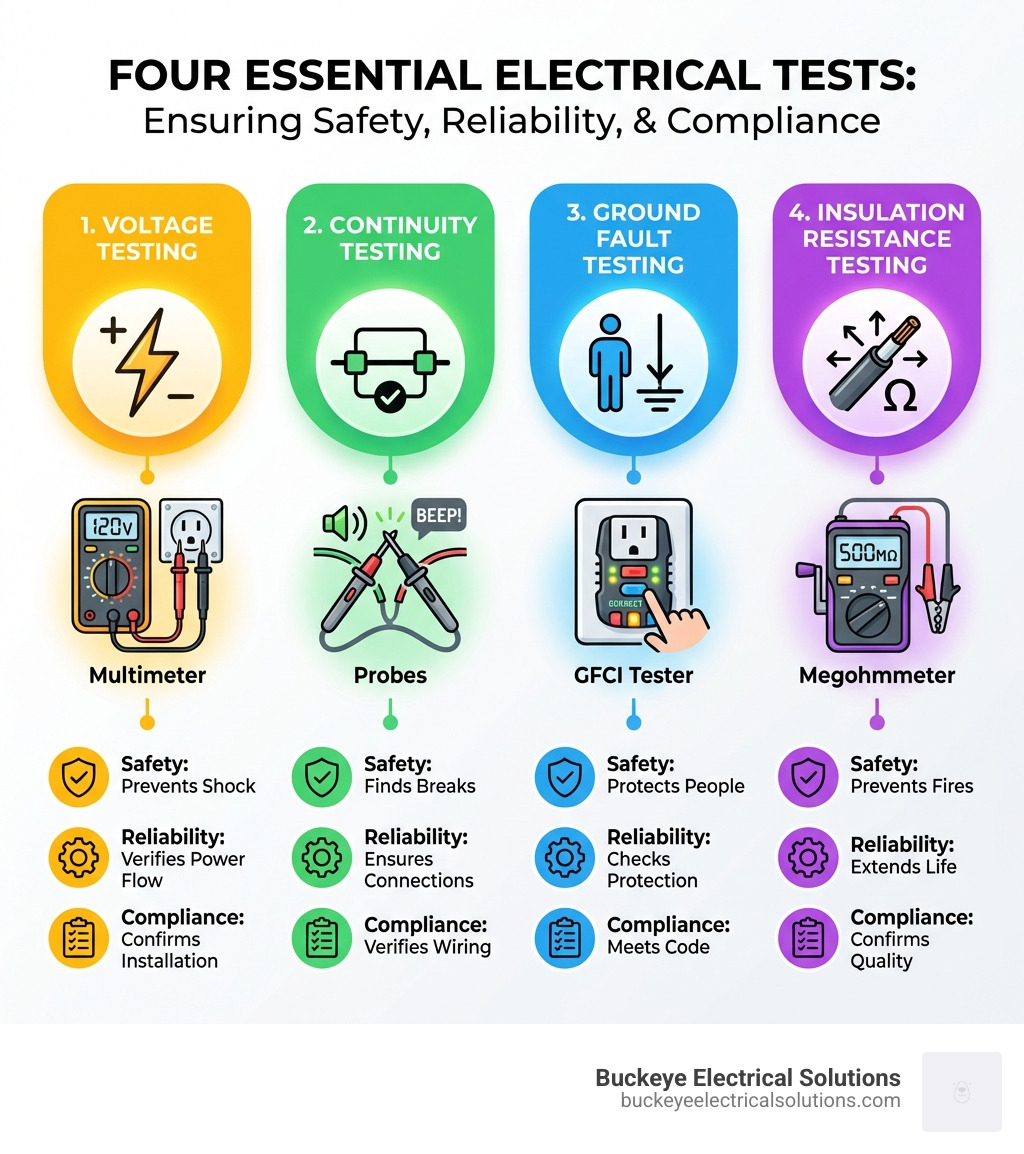

Electric test procedures are your first line of defense against electrical hazards. Whether you’re checking a dead outlet or troubleshooting a circuit, knowing how to perform basic tests can save you time, money, and potentially your life. Key tests include:

- Voltage Testing: Confirms power is present or absent.

- Continuity Testing: Verifies connections are solid.

- Ground Fault Testing: Ensures GFCI outlets work correctly.

- Insulation Resistance Testing: Checks wire insulation integrity.

According to the InterNational Electrical Testing Association (NETA), proper electrical testing is the cornerstone of safe power systems. It helps identify faults before they become major issues, preventing fires and shock hazards. Electrical testing isn’t optional; it’s a critical safety practice for any modern home, where every circuit and outlet is a potential point of failure.

The good news is that basic testing is more accessible than ever. Affordable digital multimeters and non-contact voltage testers are easy to find, and using them safely doesn’t require an engineering degree—just clear guidance and common sense.

I’m Aaron, and I’ve led Buckeye Electrical Solutions through dozens of permitted electrical projects across Northeast Ohio, from complete rewires to panel replacements, where proper electric test procedures are essential to every job. Whether you’re tackling a simple DIY project or need to understand what a professional electrician is doing in your home, this guide will walk you through everything you need to know about electrical testers and how to use them safely.

Why Electrical Testing is Crucial for Safety and Reliability

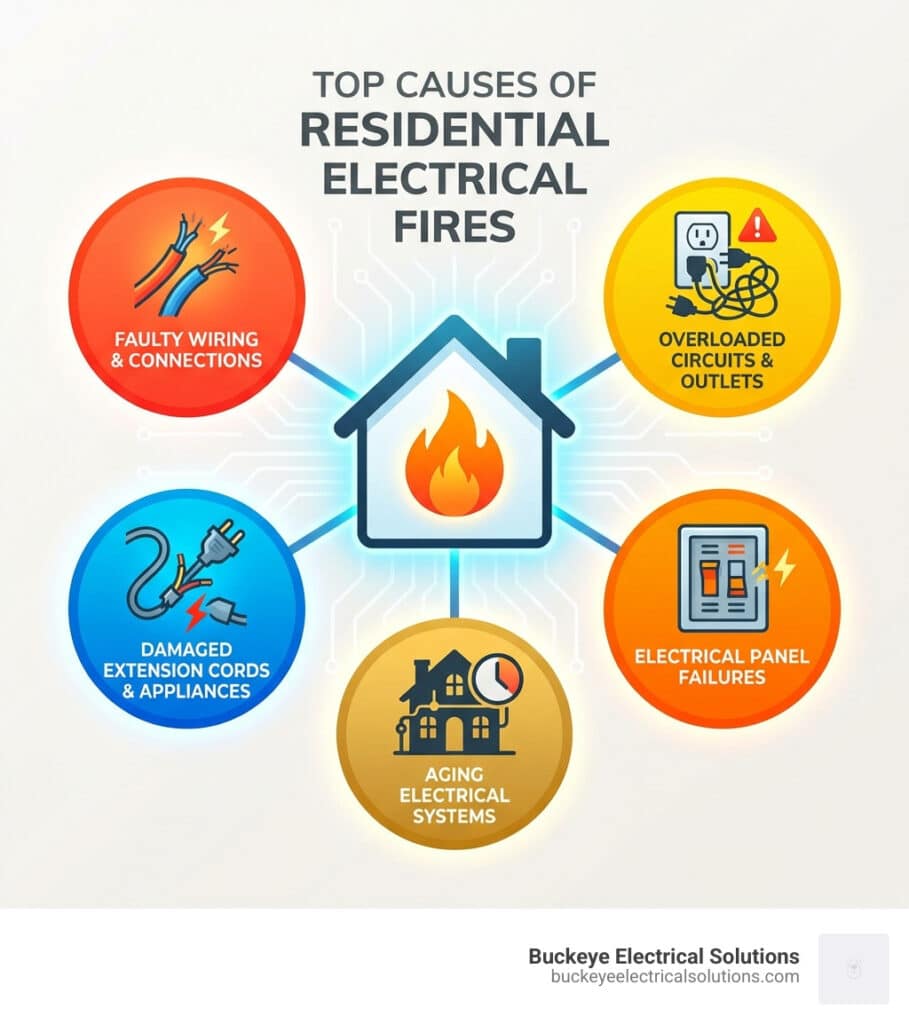

Electrical testing isn’t just a technical formality; it’s a fundamental safety practice. Faulty wiring or malfunctioning components can quickly turn a convenience into a catastrophe, which is why every electric test is a vital step in preventing electrical fires and shock. As the InterNational Electrical Testing Association (NETA) highlights, proactive testing identifies potential faults before they escalate, ensuring the continuous, reliable operation of electrical systems.

Compliance with stringent electrical safety standards, like the ANSI/NETA ATS-2025, is our best defense against the inherent dangers of electricity. Regular testing is a cornerstone of preventative maintenance, allowing us to detect subtle issues that could compromise power system reliability over time.

The Role of Testing in Preventing Electrical Hazards

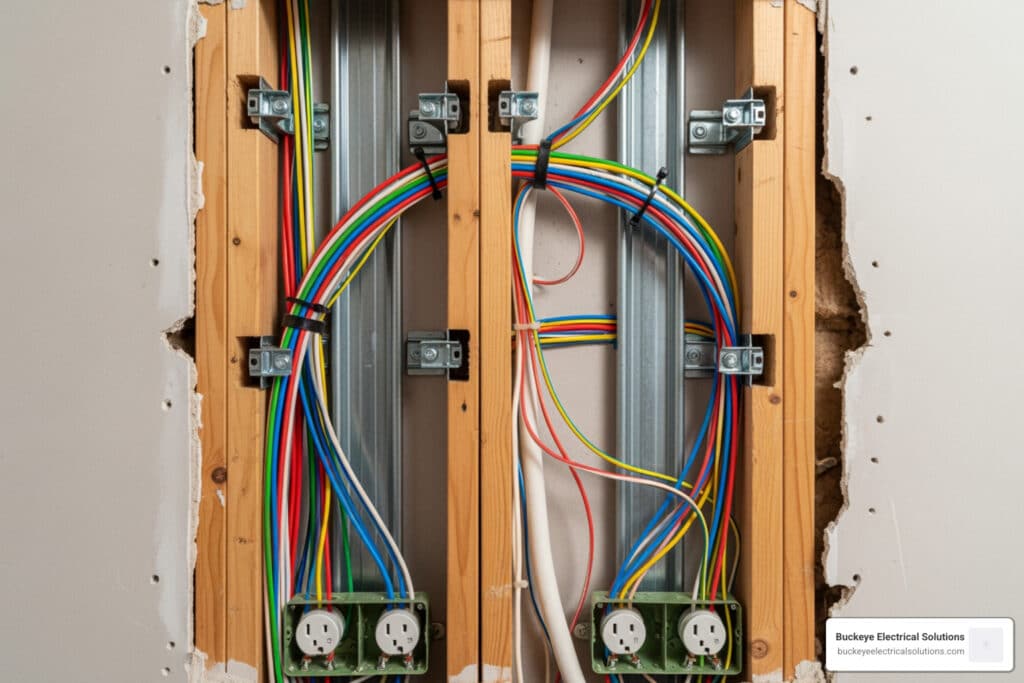

An electric test acts as a detective for unseen dangers lurking behind your walls, like frayed wires or loose connections. Our primary goal is to identify and mitigate these risks:

- Identifying Faults: Electrical tests can confirm if wires are properly connected, if insulation is intact, and if there are any incorrect installations that a visual inspection might miss.

- Verifying Protection: We test circuit breakers and fuses to ensure they trip when they should, preventing overloaded circuits from generating excessive heat and causing fires.

- Checking Grounding: Proper grounding is critical. An earth continuity test confirms that metal parts are correctly connected to earth, providing a safe path for fault currents and protecting against electric shock.

- Ensuring Safety in Residential Electrical Services: For homeowners in Northeast Ohio, regular testing is paramount. Verifying GFCI outlets in bathrooms and kitchens—life-saving devices that protect against shock—is a simple but crucial step in safeguarding your family and property.

By systematically performing these tests, we can pinpoint and address weaknesses before they cause harm. For more insights, you can refer to An overview of electrical safety testing.

Ensuring System Uptime and Performance

Beyond safety, electrical testing is a powerful tool for maintaining the efficiency and longevity of your electrical systems. Think of it as a regular health check for your electrical infrastructure that helps minimize downtime and verify performance.

For businesses, unexpected electrical failures can halt operations, leading to significant financial losses. Regular testing identifies potential problems early, allowing for scheduled maintenance rather than emergency repairs. An electric test can also evaluate the performance of individual components, ensuring that switches, relays, and all parts of a system work in harmony. This quality assurance is non-negotiable for any installation, as a single faulty component can compromise the entire setup. When new equipment is installed, this “electrical commissioning” process identifies any issues from day one, saving time and money.

In Northeast Ohio, Buckeye Electrical Solutions understands that a reliable electrical system is crucial. Our meticulous testing procedures contribute directly to the uptime and performance you expect from your electrical infrastructure.

A Breakdown of Common Electrical Test Types and Equipment

Now that we understand why electrical testing is so important, let’s dive into the “how.” Having the right tools for an electric test is essential, whether you’re a DIY enthusiast or a professional.

Here’s a list of essential electrical testing tools for your toolkit:

- Digital Multimeter: Your versatile go-to for measuring voltage, current, and resistance.

- Non-Contact Voltage Tester: For quick, safe checks of live wires without touching them.

- GFCI Outlet Tester: A simple plug-in device to verify the function of ground fault circuit interrupters.

- Circuit Breaker Finder: Helps identify which breaker controls which circuit without guesswork.

- Insulation Tester (Megohmmeter): For advanced checks of wire insulation integrity.

- Continuity Tester: For checking complete circuits, often integrated into multimeters.

Let’s explore some of the most common types of electrical tests.

Voltage Testing

Voltage testing is the most fundamental electric test, verifying the presence or absence of electrical potential. It’s used to check if power is present at an outlet or switch, which is crucial for safety before starting any work. Testers can measure Alternating Current (AC) like the 120V in our homes, and Direct Current (DC) from batteries. A non-contact voltage tester offers a quick, safe initial check, while a digital multimeter provides precise measurements.

Continuity Testing

Continuity testing checks for a complete, unbroken path for electricity to flow. This electric test is used to find breaks in wires, verify connections, and check components like fuses and switches. To perform the test, the circuit must be de-energized. Many testers have an audible beep, which conveniently signals a complete circuit, allowing you to focus on the probes rather than the screen.

Insulation Resistance (IR) Test

The Insulation Resistance (IR) test, or “meggering,” assesses the quality of the insulation surrounding wires. Over time, insulation can degrade due to age, heat, or damage, leading to current leakage, short circuits, and shock hazards. An IR test applies a high DC voltage to measure the insulation’s resistance—the higher the resistance, the better the insulation. Because this test uses high voltage, it is typically performed by trained professionals as part of a preventative maintenance program. For a deeper dive, A guide to insulation resistance testing provides technical information.

Earth Continuity and Ground Fault Testing

These tests are a cornerstone of electrical safety, designed to protect against electric shock. An earth continuity test verifies that all exposed metal parts of an appliance are correctly connected to the earth, providing a safe path for fault currents. RCDs (Residual Current Devices) and GFCIs (Ground Fault Circuit Interrupters) are life-saving devices that detect current leakage and shut off power almost instantly. We regularly perform an electric test on GFCIs in Northeast Ohio homes to ensure they function correctly, which can be done by pressing the “test” button or using a dedicated tester.

Mastering the Multimeter: A Practical Guide to Your First Electric Test

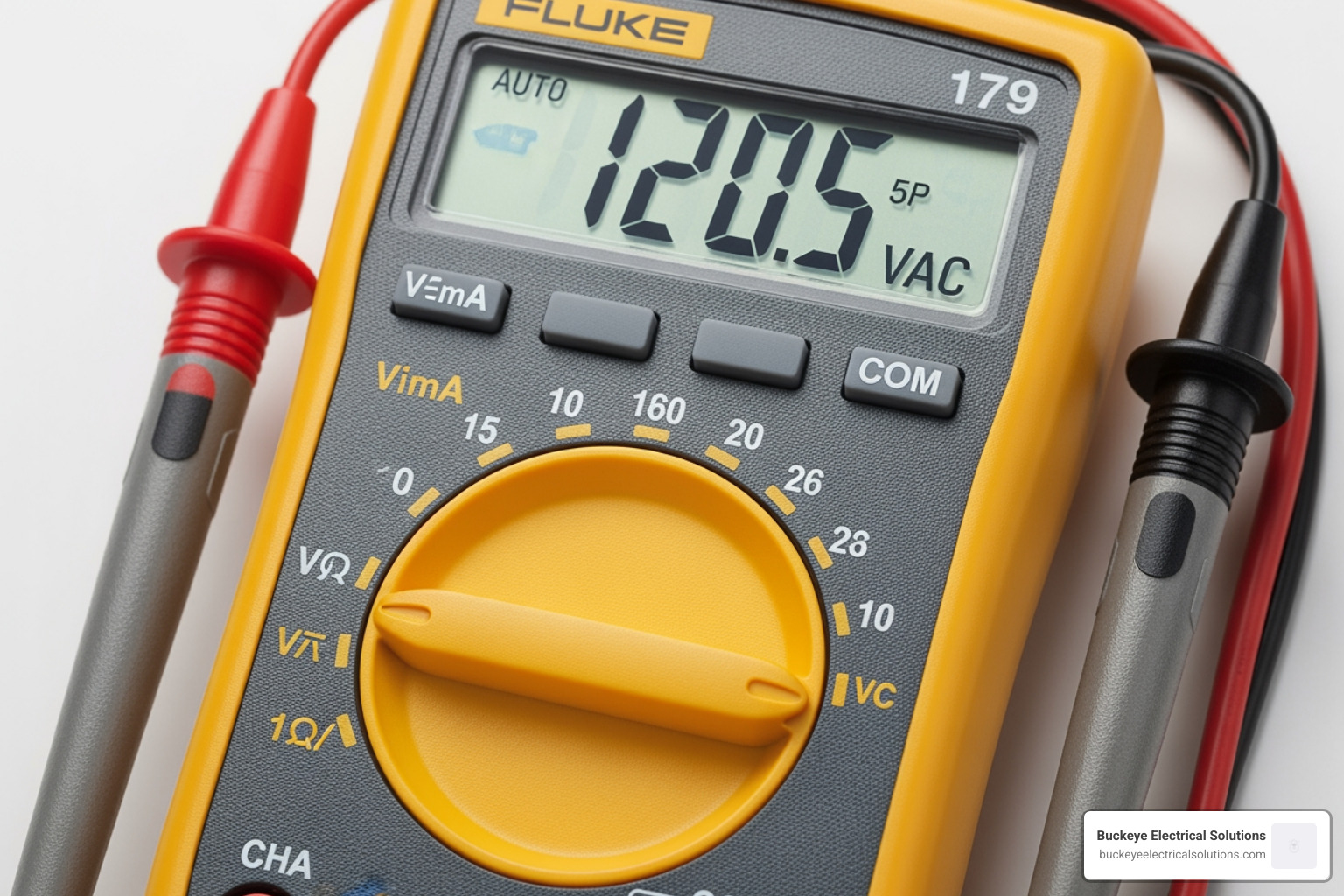

The multimeter is the most versatile tool in any electrical toolkit, capable of measuring voltage, current, and resistance.

A multimeter consists of a display, a selection dial, and test leads (probes). When choosing one, look for safety ratings (e.g., CAT III), which indicate the maximum voltage the meter can safely handle. For typical household use in Ohio, a CAT III 600V rated meter is a good, safe choice for any electric test.

Choosing the Right Multimeter

With many options available, the table below compares common types. For most homeowners, an auto-ranging digital multimeter is an excellent, user-friendly starting point. Auto-ranging models automatically select the correct measurement range, simplifying the process. TRMS (True RMS) meters provide more accurate AC readings, while clamp meters are specialized for measuring current without disconnecting wires.

| Feature | Manual-Ranging Multimeter | Auto-Ranging Multimeter | Clamp Meter |

|---|---|---|---|

| Ease of Use | Requires manual selection of range, can be intimidating for beginners. | Automatically selects the correct range, very user-friendly. | Clamp measures current without breaking circuit, often auto-ranging. |

| Features | Basic measurements (V, A, Ω), often more affordable. | Basic + advanced features (capacitance, frequency, temperature, NCV). | Primary function is current (AC/DC), often includes V, Ω, continuity. |

| Best Applications | Simple DIY tasks, learning electrical basics. | General troubleshooting, more complex DIY, professional use. | Measuring high currents, motor diagnostics, HVAC. |

| Accuracy | Good for its price point. | Generally more precise, especially with True RMS (TRMS). | Excellent for current, good for other integrated functions. |

| Safety | Standard safety ratings (CAT II/III). | Standard safety ratings (CAT II/III/IV). | High safety ratings (CAT III/IV), non-contact current measurement. |

How to Perform a Basic Electric Test on a Battery

Testing a battery’s voltage is a simple electric test that estimates its charge. Here’s a quick guide:

- Set Up: Turn the multimeter dial to DC Voltage (V with a straight line: V—). Select a range higher than the battery’s voltage (e.g., 20V for a 12V battery) if your meter isn’t auto-ranging. Plug the black lead into the “COM” port and the red lead into the “VΩmA” port.

- Connect: Touch the black probe to the battery’s negative (-) terminal and the red probe to the positive (+) terminal.

- Read & Interpret: The display shows the voltage. A fully charged 12V car battery should read ~12.6V; a 1.5V AA battery should read ~1.5V. A significantly lower reading indicates a discharged or failing battery.

How to Safely Test a Wall Outlet

Testing a wall outlet requires extreme caution as you are dealing with live electricity. Always wear insulated gloves and safety glasses.

- Initial Check: Use a non-contact voltage tester first. Touch its tip to the smaller vertical slot (hot). If it beeps or lights up, power is present.

- Set Multimeter: Turn the dial to AC Voltage (V with a wavy line: V~). Choose a range above 120V (e.g., 200V or 600V) if not auto-ranging.

- Test Hot to Neutral: Insert the red probe into the smaller (hot) slot and the black probe into the larger (neutral) slot. The reading should be ~120V.

- Test Hot to Ground: Leave the red probe in the hot slot and move the black probe to the round (ground) hole. The reading should again be ~120V.

- Test Neutral to Ground: Move the red probe to the neutral slot and keep the black probe in the ground hole. The reading should be close to 0V.

Interpreting Results: Correct readings (~120V Hot-to-Neutral/Ground, ~0V Neutral-to-Ground) mean the outlet is likely wired correctly. No voltage suggests a tripped breaker. Other readings indicate a wiring problem. If you find any unexpected results in your Northeast Ohio home, contact a qualified electrician.

The Professional Standard: NETA, Certifications, and When to Call an Expert

While basic electrical testing is accessible to homeowners, complex systems demand a higher level of expertise and adherence to stringent standards set by organizations like NETA.

What are NETA Standards?

The InterNational Electrical Testing Association (NETA) is a globally recognized authority in the electrical testing industry. As an American National Standards (ANSI) developer, NETA publishes comprehensive standards, such as the ANSI/NETA ATS-2025, for testing electrical power equipment. These standards provide a uniform, rigorous approach to testing that ensures quality, promotes safety, and establishes consistency across the industry. NETA also shares knowledge through publications like the NETA World Journal, keeping professionals informed on the latest trends and technologies.

The Benefits of Hiring a Certified Professional

For complex or high-voltage applications, the expertise of a NETA Accredited Company (NAC) or a certified professional is invaluable. While we at Buckeye Electrical Solutions empower homeowners with knowledge, we know when professional intervention is necessary.

Here’s why hiring a certified professional in Northeast Ohio makes all the difference:

- Complex Systems: Professionals have the training to steer the intricacies of commercial and industrial electrical systems, which involve higher voltages and specialized equipment.

- High-Voltage Safety: Certified technicians are trained in the specific safety protocols required to perform a high-voltage electric test without incident.

- Code Compliance: Professionals are well-versed in the National Electrical Code and local Ohio regulations, ensuring all work is legal and safe. This is crucial for Commercial Electrical Services, where non-compliance can lead to fines and shutdowns.

- Safety Assurance: A certified professional’s rigorous training and adherence to standards provide unparalleled safety assurance, minimizing risks to people and property.

At Buckeye Electrical Solutions, our team brings over 20 years of experience to residential and commercial electrical work across Northeast Ohio. We understand the critical role of expertise in ensuring the safety and reliability of your electrical systems.

Conclusion

Understanding the basics of electric test procedures and how to use common electrical testers is a powerful step towards a safer and more reliable electrical environment in your home or business. We’ve explored why electrical testing is crucial, detailing its role in preventing hazards like shocks and fires, and ensuring your systems run efficiently. From verifying voltage and continuity to understanding more specialized tests like insulation resistance and ground fault checks, each test plays a vital part in maintaining electrical health.

We hope this guide has demystified the multimeter, empowering you to perform basic tests on batteries and wall outlets with confidence and, most importantly, with an unwavering commitment to safety. While DIY efforts are commendable for simple tasks, there are inherent limitations. Electrical work can be dangerous, and complex systems, especially those involving high voltage or commercial applications, always warrant the expertise of a certified professional.

At Buckeye Electrical Solutions, we are proud to be a trusted electrical contractor in Northeast Ohio, known for our exceptional service and prompt project completion. We believe in empowering our community with knowledge, but we also know when to step in. For comprehensive and safe electrical system evaluations, complex installations, or any concerns beyond basic troubleshooting, trust the experts. Our experienced team is ready to ensure the safety, efficiency, and reliability of your electrical infrastructure.

For all your electrical service needs in Northeast Ohio, don’t hesitate to contact us. We’re here to help keep your lights on and your systems safe.